XaaS – X-ray as a Service

Efficient X-ray inspection services

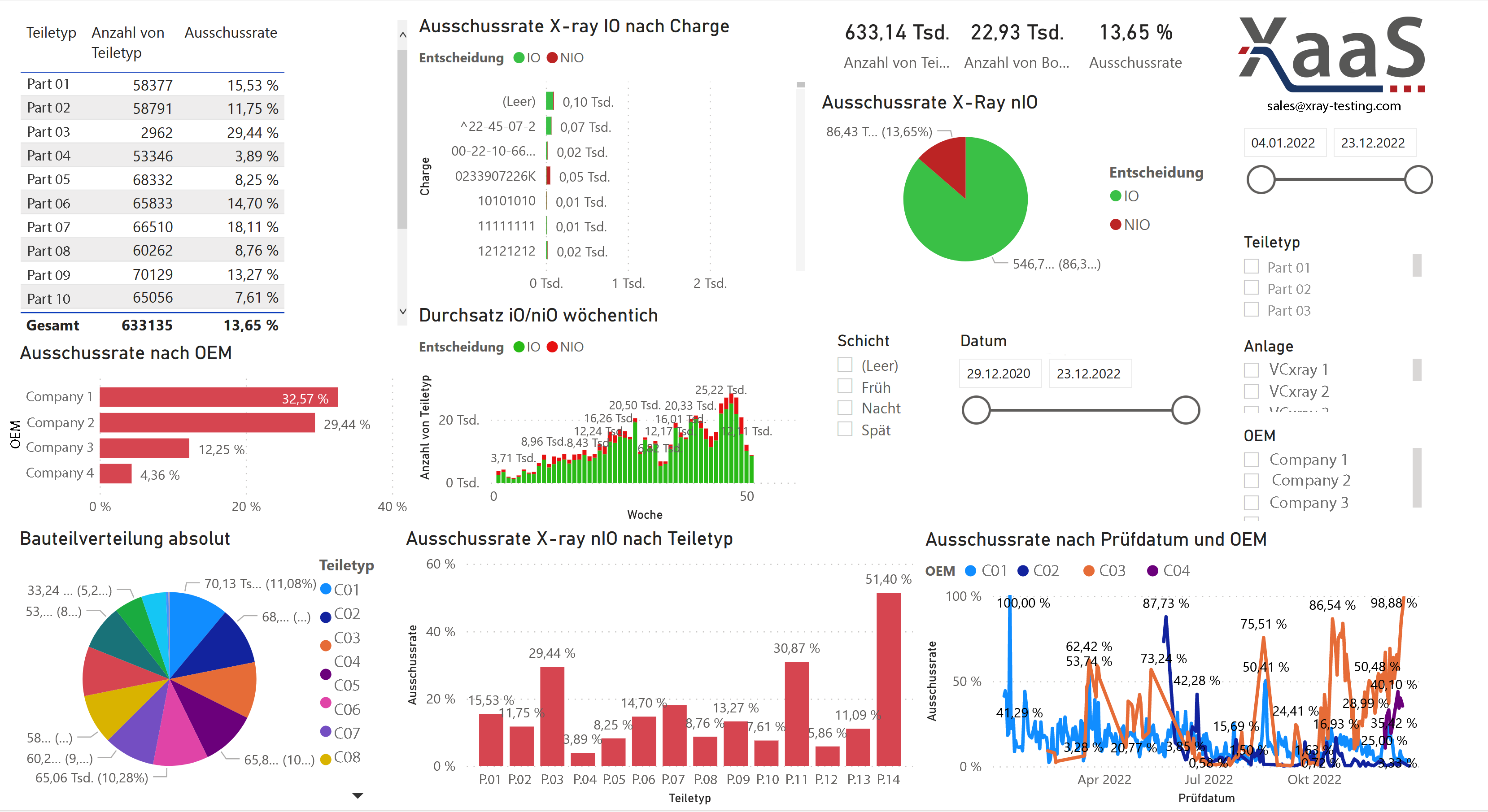

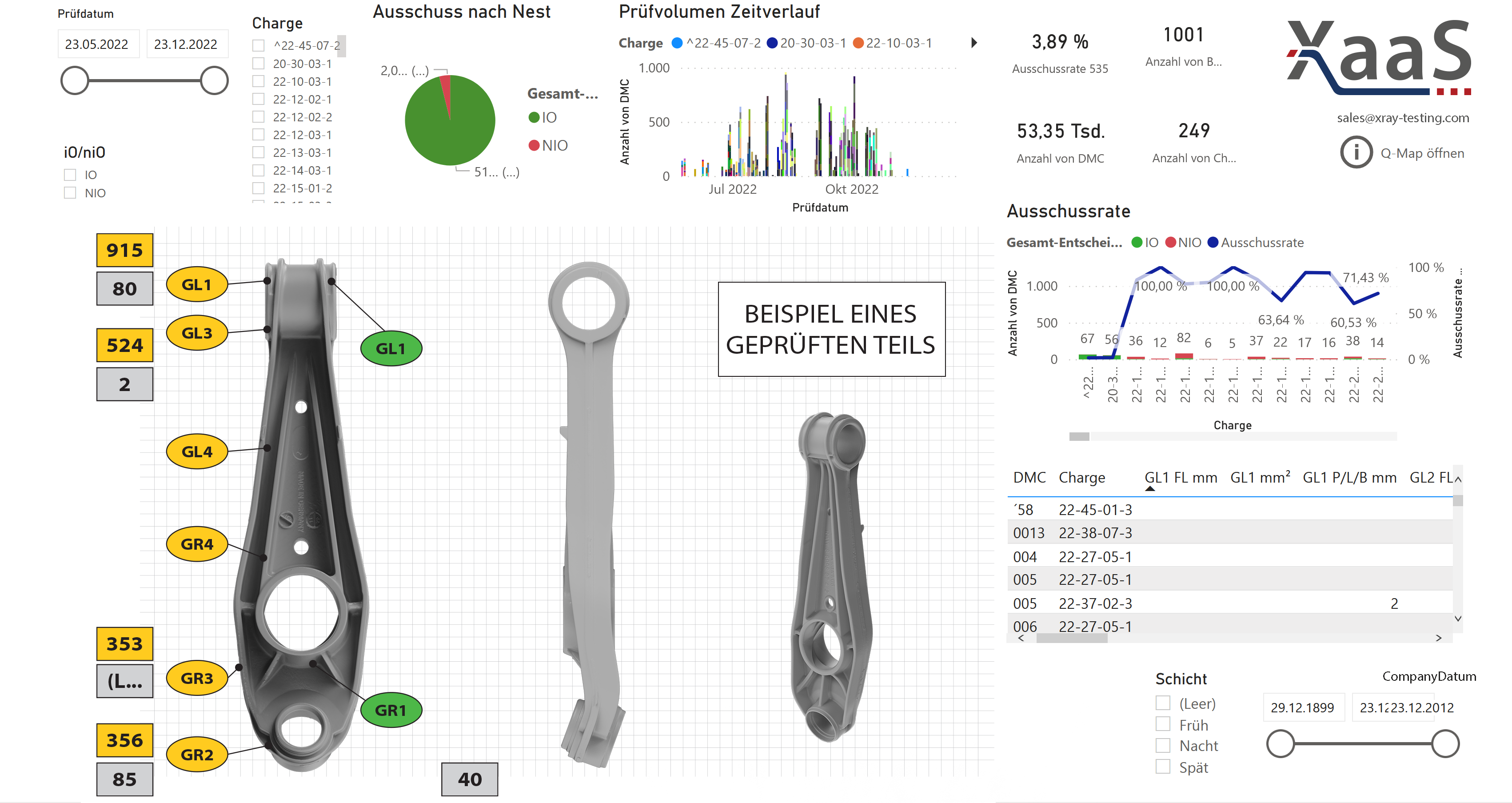

We check, you overview

Challenges of today‘s inspection services

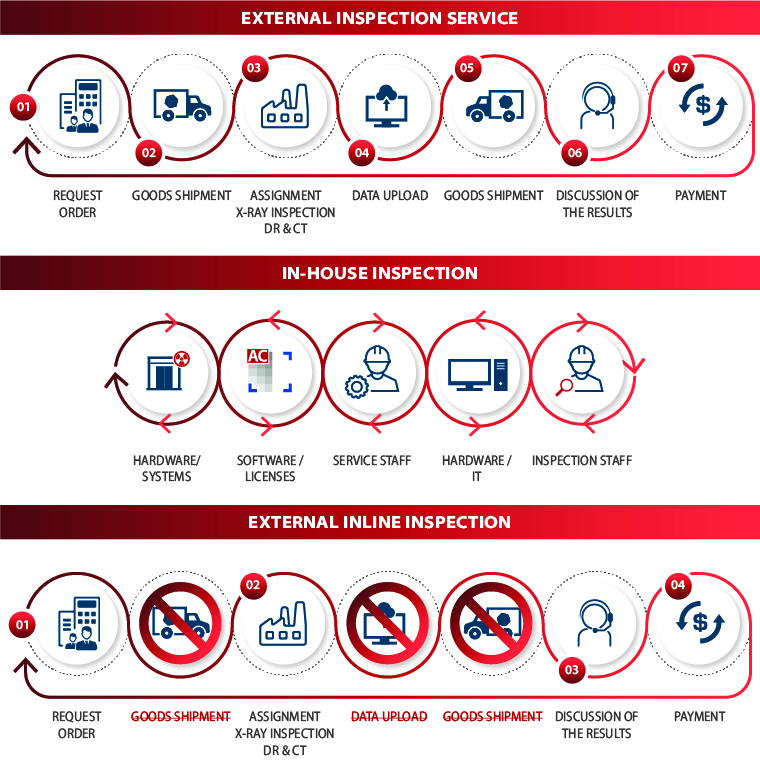

External inspection service

Complete outsourcing of component inspection results in additional costs for transporting the components and an associated increase in testing time.

In-house inspection

With in-house inspection, the high investment in an in-house testing facility as well as appropriate, qualified personnel is a prerequisite.

External inline inspection

Inline inspection moves external testing into production. However, implementation requires qualified experts on site.

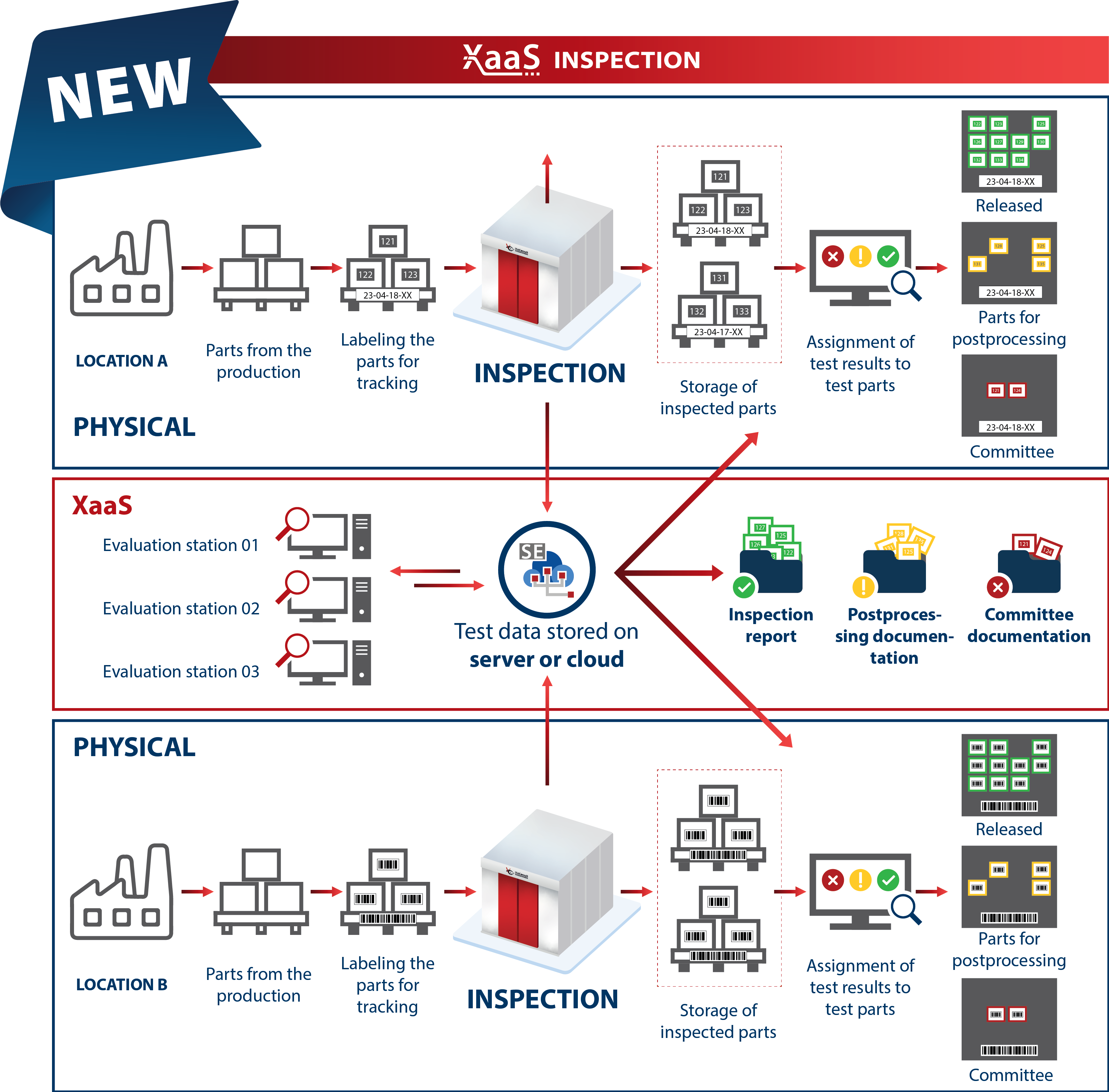

The new model for your component testing

XaaS the more efficient inspection service

The XaaS combines all the advantages of the previously mentioned models and combines them with a geographically unbound cloud system. The location of the X-ray inspection thus no longer plays a role. The physical part remains on the premises, but the know-how and the evaluation are geographically independent.

At the customer‘s site, only the inspection system has to be loaded with components, which reduces personnel costs. Thanks to a high cycle rate, an increased quantity of components is x-rayed in a short time. This means that the components remain in the factory, transport costs are eliminated, and personnel costs and throughput times are minimized. At the end of the process, the customer receives a clear evaluation.

All advantages without compromise

The main advantages of the XaaS-Models in direct comparison with the conventional models

are as follows

- Seamless integration into existing processes

- Balance sheet neutral – No

investment in hardware required - Vendor independent – own

equipment can be integrated - All costs are variable – easily

scalable up or down - Added value and savings even from small component quantities

- Immediate return on investment

and savings guaranteed - No in-house, qualified inspection

personnel required - Independence from external testing companies

- Fast inventory turnover, no shipping costs

and an improved carbon footprint - Short term – up to contour shift models

- Maintenance/service included with VCxray

systems – no unexpected costs - XaaS models for RT and CT