Industrial Computed Tomography (3D)

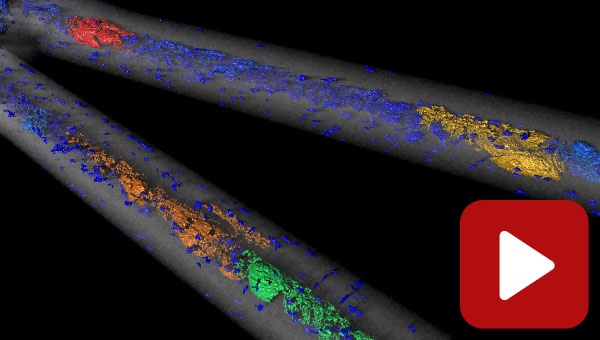

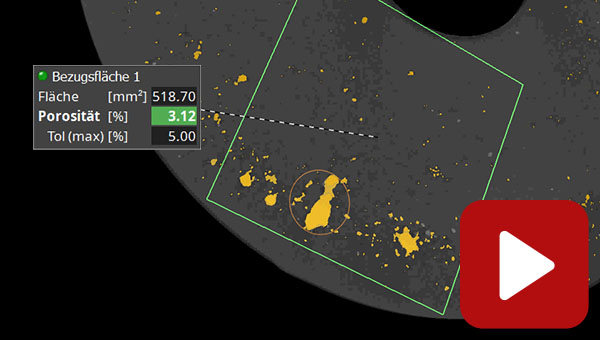

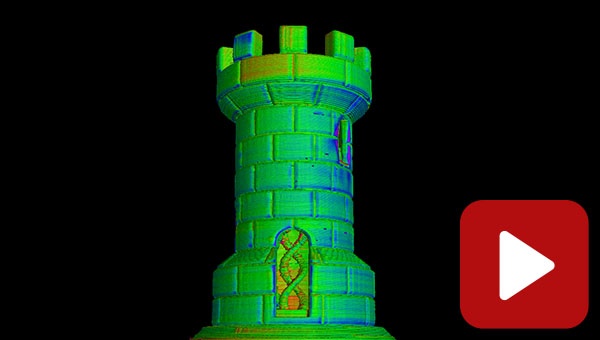

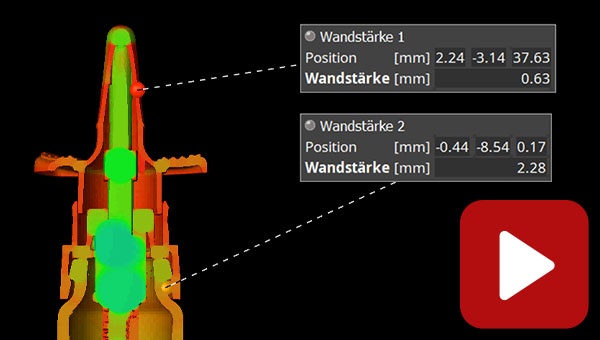

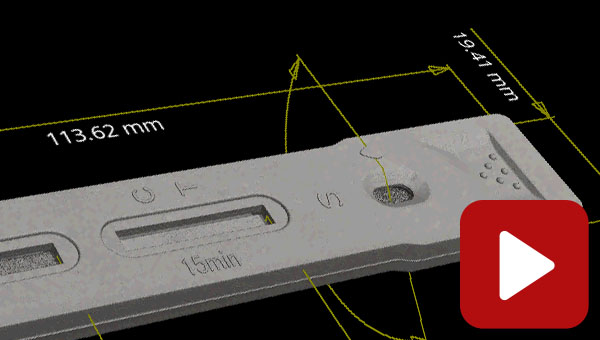

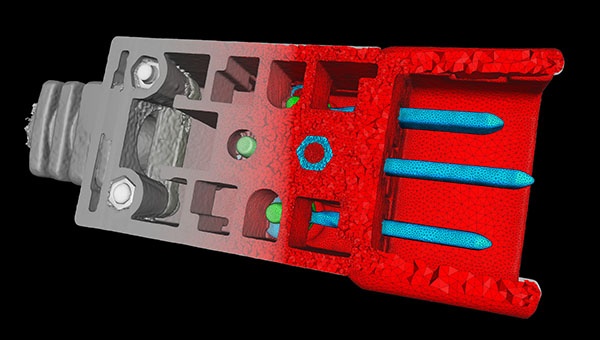

A picture is worth a thousand words, and likewise a CT scan reveals the full information about the integrity of your components. Industrial computed tomography (CT) takes your quality assurance to the next level with “extra insights”. We would be happy to take a look at your component throughCT in 3D, contact us!

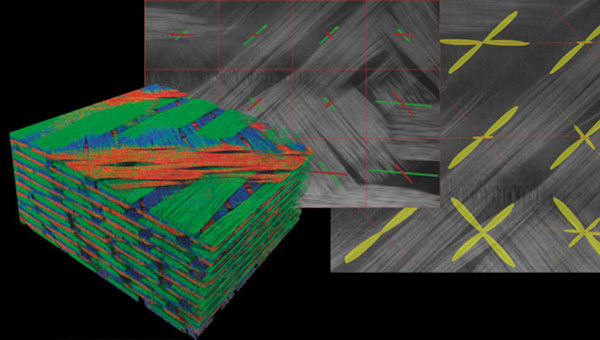

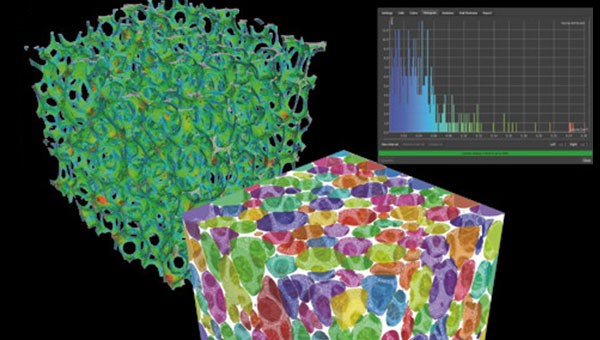

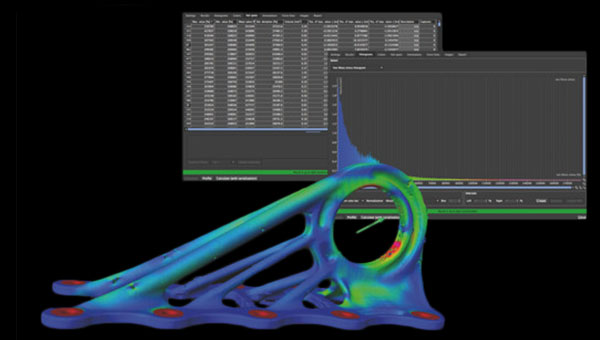

Industrial CT is gaining more and more relevance in quality assurance. The reasons for this is, besides the fully comprehensive defect localization and classification, the constantly growing inspection requirements. There can be various reasons for this, such as increasingly complex component geometries and structures. Thanks to the three-dimensional data acquisition of CT and the associated evaluation options, comprehensive and localizable statements about the component quality can be derived and precise measures can be taken on the basis of these.

Advantages of CT testing

Our CT specialists will be happy to assist you personally under the respective contact details or alternatively via our inquiry form.